Fabrication at FTE. A Design Engineer’s Delight

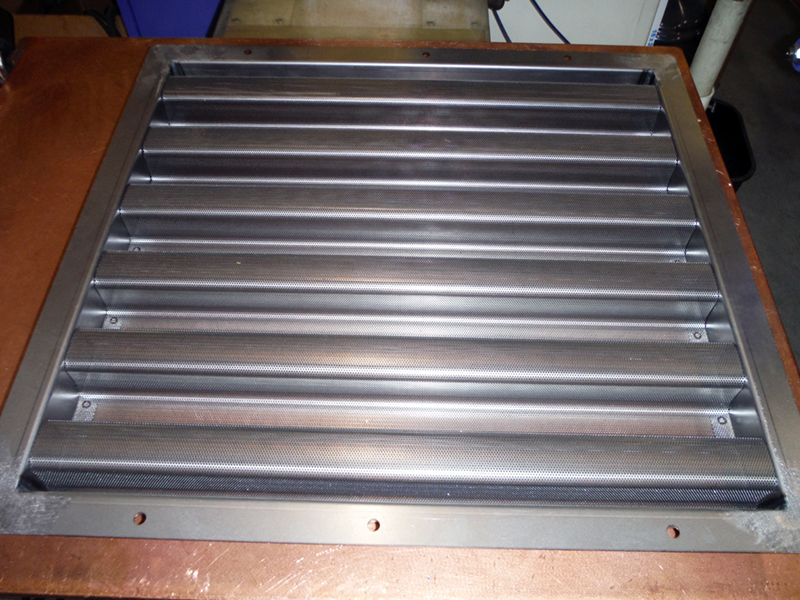

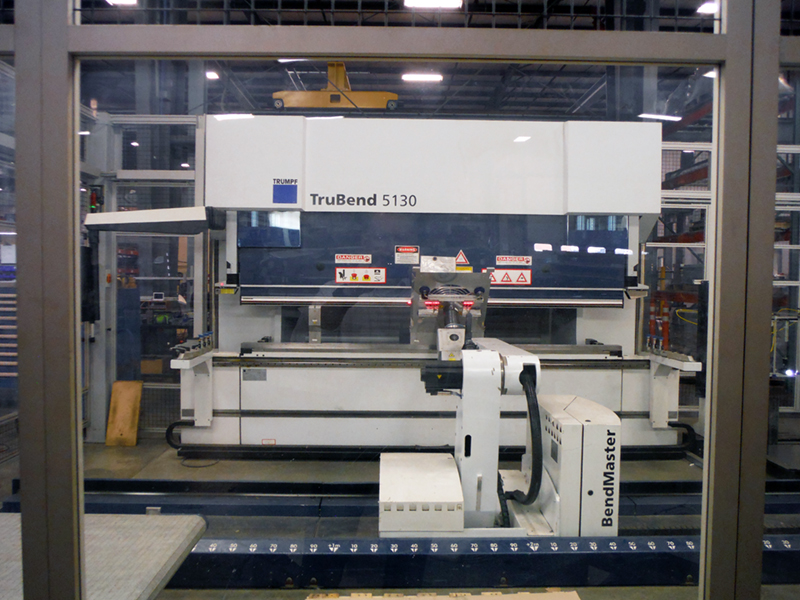

When it comes to metal fabrication, Federal Tool & Engineering knows its business of cutting, bending and assembling. Our capabilities include state-of-the-art fiber laser and robotic bending.

Whether working with Aluminum, Brass, and either Carbon or Stainless Steel, our broad capabilities create a wide range of flexibility to effectively support the diverse needs of our customers.

Cutting can be done by traditional methods or is often completed by CNC laser. While press brakes are often in use, bending will take on different forms and processes dependent upon the desired outcome. And when focused on the function of assembly, the options are as numerous as the options to fasten from adhesives to welding.

FTE Fabrication at a glance:

- .010″ thick to .500″ thick

- Commercial and Decorative Surface Finishes

- Laser, Turret, Press Brake

- Welding: MIG/TIG, Resistance, Robotic, Manual

- Drilling Tapping, Machining

- Pem Insertion

- Washing and De-burring

Let us put our track record of fabrication success to work for you. Contact us to discuss your next project.